Liquibox Orbiter®

Liquibox Orbiter:

Fully-automatic

rotary bag-in-box filler

I understand that this information will be used to address my inquiry and to receive updates from Liquibox.

The fastest single footprint bag-in-box system in the market

With the Liquibox Orbiter rotary filler, you get increased speed, increased capacity, increased revenue, and reduced total cost of ownership. This filler is specially engineered for the challenges of high volume, producing up to 7,500 gallons (30,000 liters) per hour, while taking up less space and only requiring a single operator.

High speed

The unique design of the Orbiter includes six filling, capping and metering systems. It’s the equivalent of having six individual machines uniquely designed into one state-of-the-art system.

Long-term reliability

The Orbiter’s six heads and fluid rotary motion offer a significantly reduced cycle rate compared to a web-fed strip filler. By decreasing cycle time, the system experiences less wear and tear, resulting in more output, more efficiency and more reliability.

Low total cost of ownership

By only requiring a single operator, reducing the costs of parts and utilities and maximizing floor space with a small footprint, the Orbiter lets you focus your resources on what is most important to your customers.

Specifications

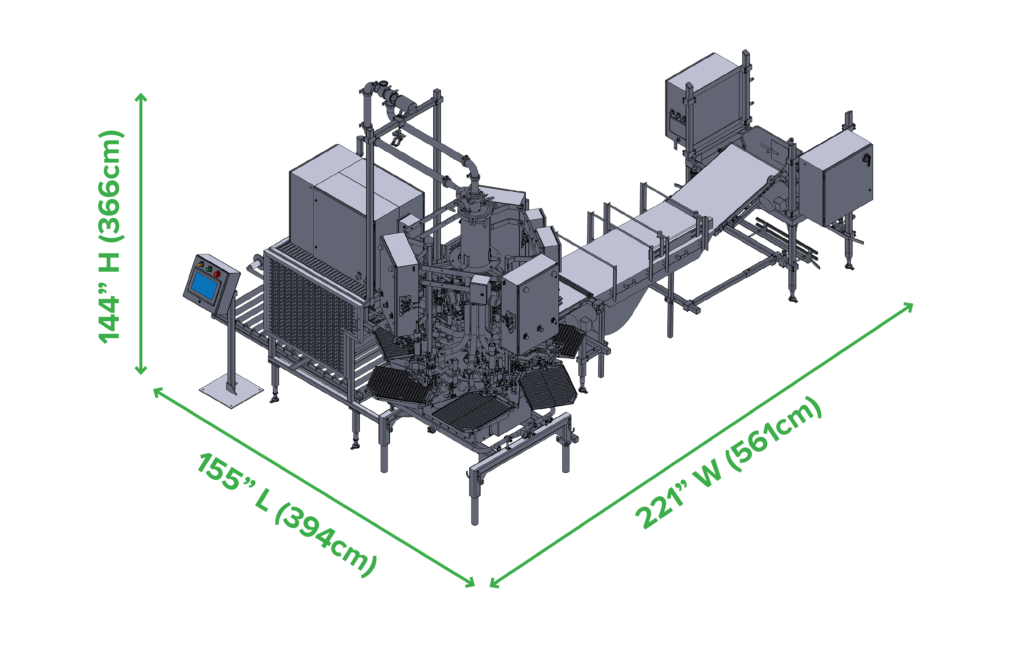

Dimensions

Filling rate

Actual rates are dependent on product type, fitment size, downstream equipment, product piping, and other installation variables. The rates below are based on filling water at 125 gallons/minute (GPM).

| Volume G (L) | Bags per minute (BPM) |

| 1G (4L) | 32+* |

| 2.5G (10L) | 32* |

| 5G (20L) | 25 |

*Based on filling 2 or more bags/box

Standard features

The Orbiter is capable of packaging conventional and Extended Shelf Life (ESL) products in 1 to 5G (4 to 20L) bag-in-box sizes. Every machine is equipped with the following features:

- Allen-Bradley or Siemens controls

- Servo driven pusher for speed, accuracy and repeatability

- Filling accuracy +/- 0.3% by volume

- 1” magnetic flow meter

- Automatic Clean-in-Place (CIP) function

- Improved safety with protective guarding

- Multiple outfeed and loading options: flat drop or tail drop loading

- Quick bag size changeover

- Variety of fitment options

Industries

Beverage

Water, post-mix syrup, juice, dairy, wine, among others.

Liquid food

Dairy & dairy alternatives, edible oil, condiments & sauces, among others.

Non-food

Motor oil, paint, coatings & varnishes, chemicals, cleaning, among others.

Related Pages

Let’s

connect

From greater sustainability to higher performance, we’re here to deliver what your business needs most.

Filler sales and support: + 1-888-472-3400